|

|

The HTSC group has an access to a set of technological equipment for thin film preparation and laboratory measurement system for low temperature electrical measurements.

Technological equipment

|

The technological complex of the "Thin Film Oxide Electronics" Laboratory includes clean room of the "1000" class, with a complete set of equipment for photolithography (spinner, oven, hot plate, mask aligner, chemical bench, de-ionized water source). The mask aligner

is working in near UV light, providing line resolution of photolithography process down to 1 µm. Sencitive microscopes and profilometers allow immediate checks of the obtained thin film structure's geometry. Thin film deposition

systems provide high- and ultra-high oil-free vacuum and a possibility of thin film deposition using variety of deposition techniques: DC- and RF-sputtering, reactive sputtering. Plasma

and ion etching systems provide additional technological processes to implement a new thin film technology using many types of materials from metallic to ceramic and insulating.

The technology of high-temperature superconductors is not that sophisticated yet, but multi-element composition, complicated crystal structure and high anisotropy of these materials present a real challenge to a technologist. The main problem is chemical compatibility of the high-temperature superconductor and metallisation/insulation/barrier materials. Deposition of the HTSC thin films is performed at high temperatures (about 800 °C), and usually demands relatively high oxygen pressures during deposition. Not many materials can withstand such a treatment, and the set of materials used together with the HTSC is limited almost to oxides group. We have rebuilt a Z-400 high-vacuum deposition system ("Leybold", Germany) and self-made magnetron sputtering system for depositions of oxide materials at high temperature and high oxygen pressure. The self-made heater, controlled by an "Eurotherm" temperature controller provides heating up to 820 °C with accuracy of 1 °C. The oxygen flow to the chamber is set by a flowmeter while the rotary-vane pump is filled with the PFPE liquid, resistive to the chemically aggressive gases like oxygen. The deposition is usually done in argon/oxygen mixture to improve stability of the discharge and decrease negative-ion bombardment of the growing film surface. The pressure is controlled precisely with a capacitive vacuum meter. The deposition rate can be monitored with a quartz deposition rate sencor. The whole process is very complicated and accurate tuning of all deposition parameters is necessary.

|

|

|

Electrical measurements equipment

|

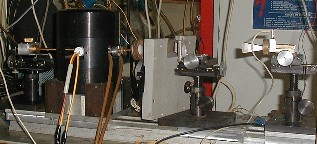

Another important part of HTSC group equipment is the low-temperature measurement systems for precise investigations of electrophysical properties of superconductive structures. Typically this kind of investigations is done by measurement of the current-voltage curves (CVC) of the sample. The computerized CVC measurement system is shown on the figure; the electronics block sets the current through the sample in accordance with the signal from the computer (Pentium-II PC) and amplifies the voltage from the sample. The amplified voltage is fed to the ADC and the digitized result is stored by the measurement program. This measurement system allows simultaneous passing of two calibrated currents through the sample circuits and amplification of two voltage signals; additional signals can be stored, like magnetic field in the sample vicinity, temperature readings, and differential resistance measured with a lock-in amplifier. The last two allow precise measurement of the R(T) curve and, thus, determination of the sample critical temperature and evaluation of structure perfectness. Other typical measurements, performed in this system, are Ic(H) - dependence of superconductor critical current on the external magnetic film, providing information of on the Josephson junction integrity; RD(V) - differential resistance dependence on voltage, revealing internal features of the Josephson junction and the HTSC material itself; and measurements of the CVC under external electromagnetic irradiation. These last ones are usually done using mm-wavelength and sub-mm-wavelength irradiation and are especially important for design and testing of Josephson effect detectors of electromagnetic radiation.

All measurements are performed at temperatures below the room temperature; to achieve low temperature cooling liquids (liquid He and liquid nitrogen) are used. In the most simple case the sample is dipped into the liquid cooling agent in the transport dewar. Special dip-sticks are designed, providing precise measurement of temperature and magnetic field, feeding of the sample with current, measurement of the signal voltage, and waveguide for the external mm-wavelength irradiation. To avoid effects of air liquification, the air is pumped out of the dip stick, and the volume around the sample is filled with helium. The whole system is placed in a screening box, decreasing the external noise, especially the radio-frequency noise and external magnetic noise.

Our second measurement system allows studies of electrophysical properties of the HTSC samples under external sub-mm-wavelength irradiation. This kind of irradiation is fed into the cryostat with the sample using an optical line, consisting of set of lenses for microwave irradiation. The CVC measurements are done the same way, as in the first measurement system.

|

|

Summarising, the "Thin Film Oxide Electronics Laboratory", has the following equipment:

- Technological complex for superconductive electronics device fabrication, including:

- clean room of class "1000";

- high-vacuum systems for thin-film deposition of normal metals and insulators using magnetron sputtering;

- set of photolithography equipment (spinner, oven, chemical bench, etc.) with mask aligner MJB-3HP ("Karl Zuss", Germany) with lithography resolution down to 1.0 mm;

- set of measurement equipment for the lithography processes;

- reactive plasma etching system, ion-beam etching facility.

- High-vacuum plant Z-400 ("Leybold AG", Germany) rebuilt for epitaxial growth of oxide films at high deposition temperatures:

- high-Tc superconducting (YBa2Cu3Ox) thin films, and

- growth of dielectric films like cerium (CeO2) and zirconium oxides (ZrO2)

with the heater which allows to obtain the temperature up to 870 °C in the oxygen atmosphere.

- High vacuum system for epitaxial growth of thin films of metal oxides (manganites , cuprates , etc.) by magnetron sputtering at high pressure, which allows to produce multilayer epitaxial structure without breaking the vacuum system. It equipped with heater of the substrate up to 900 °C and a system of independent control of magnetron guns.

- High vacuum system for etching of oxide films in the ion beam with the energy of the ions 50-1500 V, equipped with a solid state cooling of the substrate holder and allows to obtain micron-sized structure without changing of the stoichiometric composition of thin films of nanometer thickness.

- A system for processing substrates, including the bonding set up Kulicke & Soffa 4129, cutting system Buehler Isomet substrates and high-temperature furnace Leybold Heraeus annealing the samples in oxygen to temperature of 1200 °C.

- Screening box and filter system for the precise automated DC measurements with low external noise. Several cryostats for measurements of the electrical transport properties at temperatures T = 3 - 300 K and magnetic fields B = 0 - 1 T. Measurement systems are controlled by data acquisition systems on the basis of PC and high-sensitive lock-in amplifiers PAR5301, PAR5210 ("EG&G", USA) and nano-voltmeters Keithley 2001, Keithley 1801, ("Keithley", USA).

- System for automated measurement and electro- magnetic and microwave characteristics in the millimeter wavelength range from 10 mm to 2 mm, equipped with a generator G4 -141, G4- 142 and amplitude –frequency meter P2 -68, P2 -69.

|